Makerspace Means Sweet Success for Students Engaged in Engineering Design

UA biomedical engineering sophomores in new maker class showcase their gadget-design and computer-programming skills in candy-sorting competition.

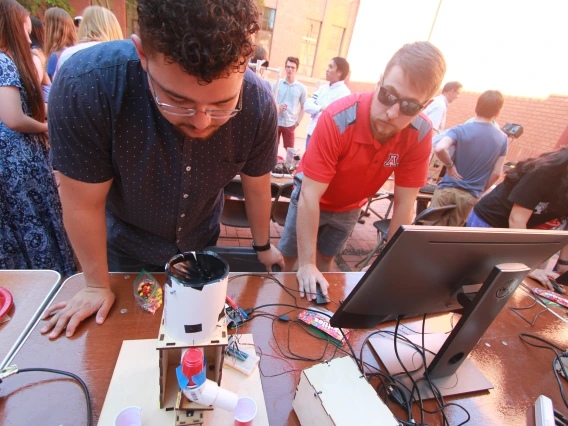

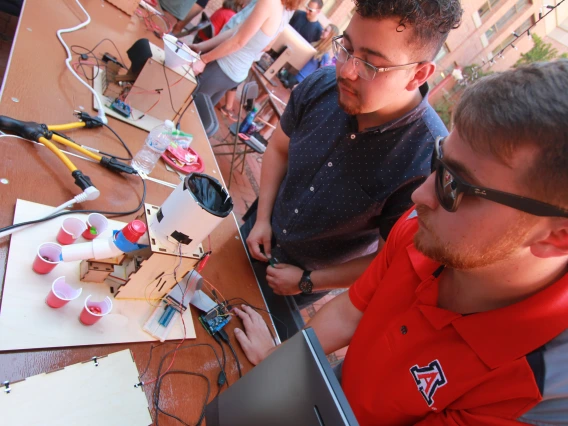

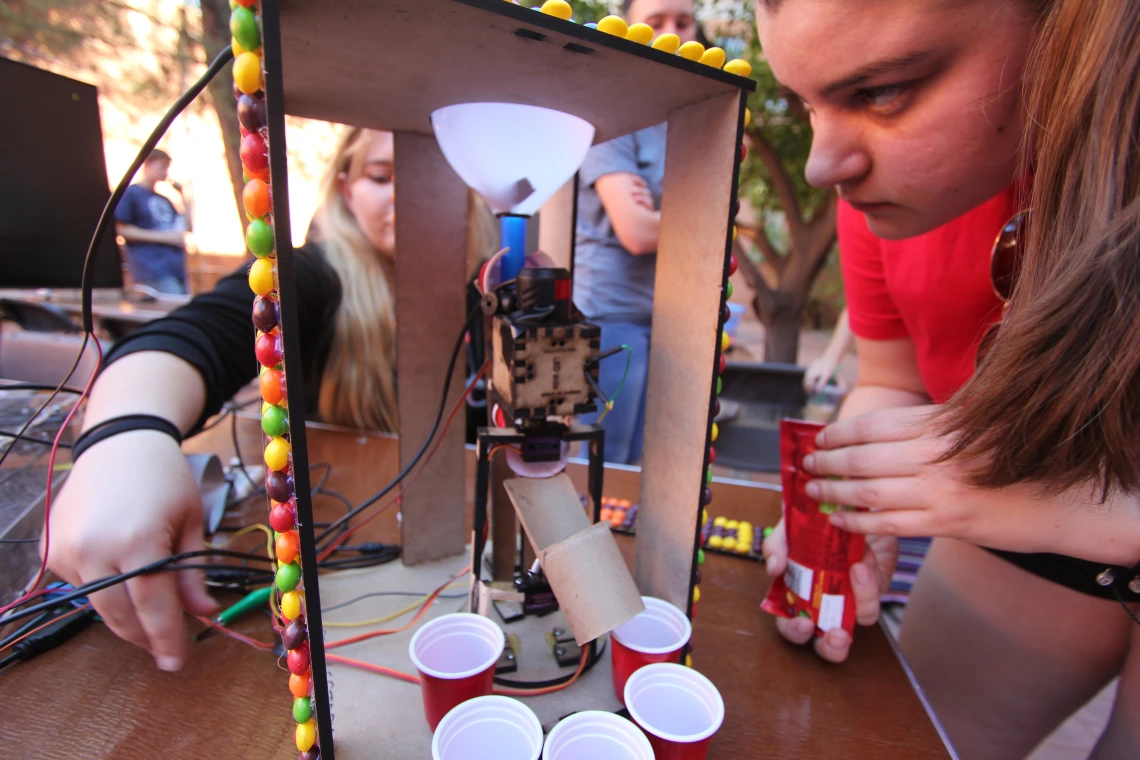

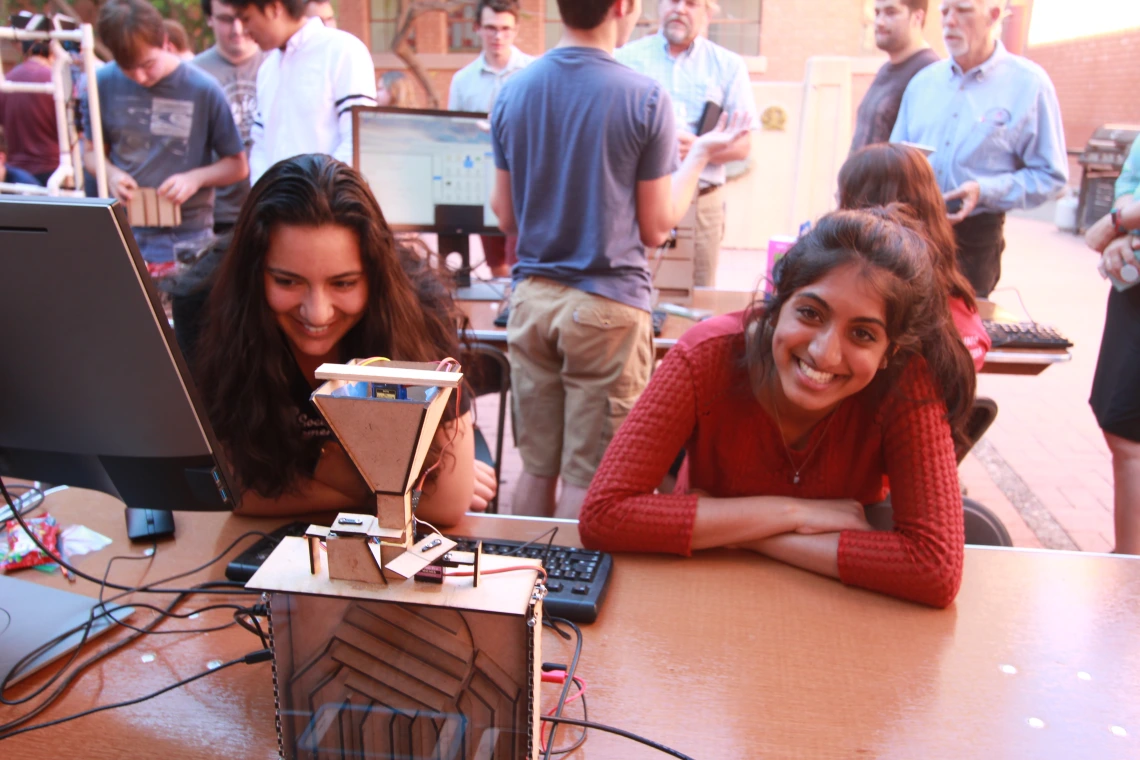

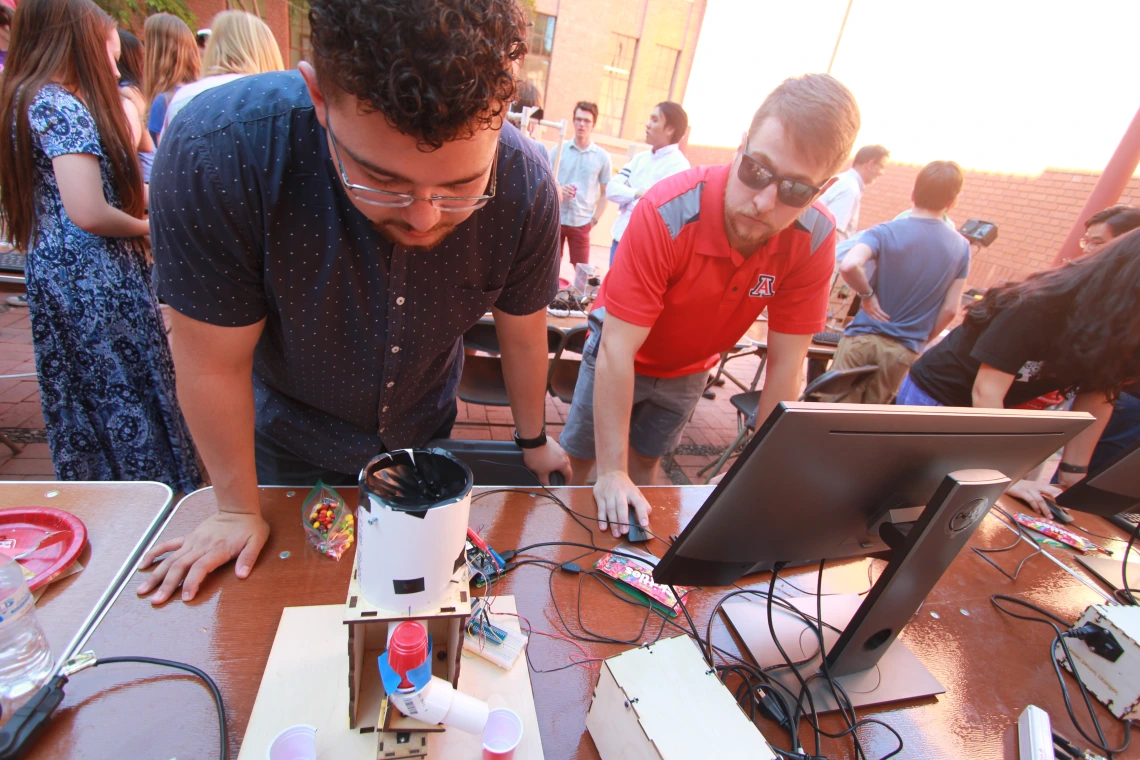

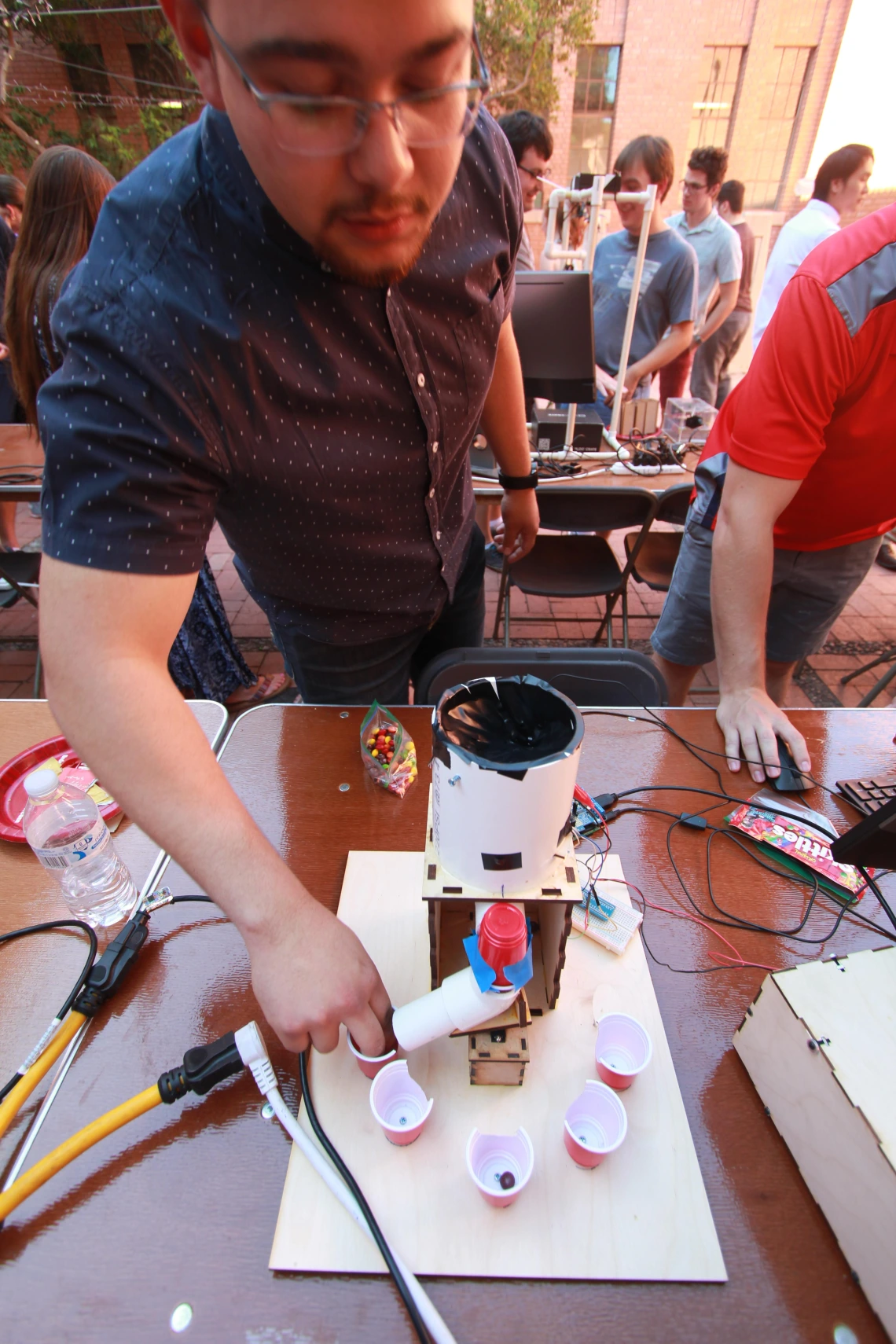

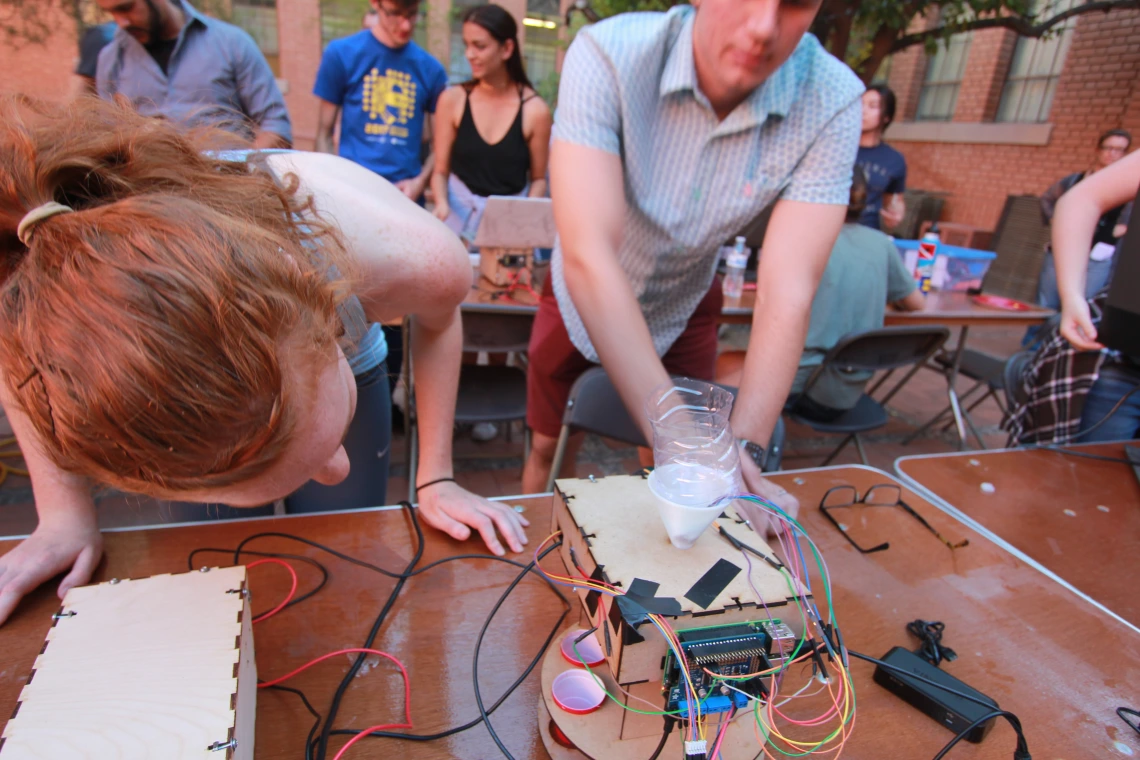

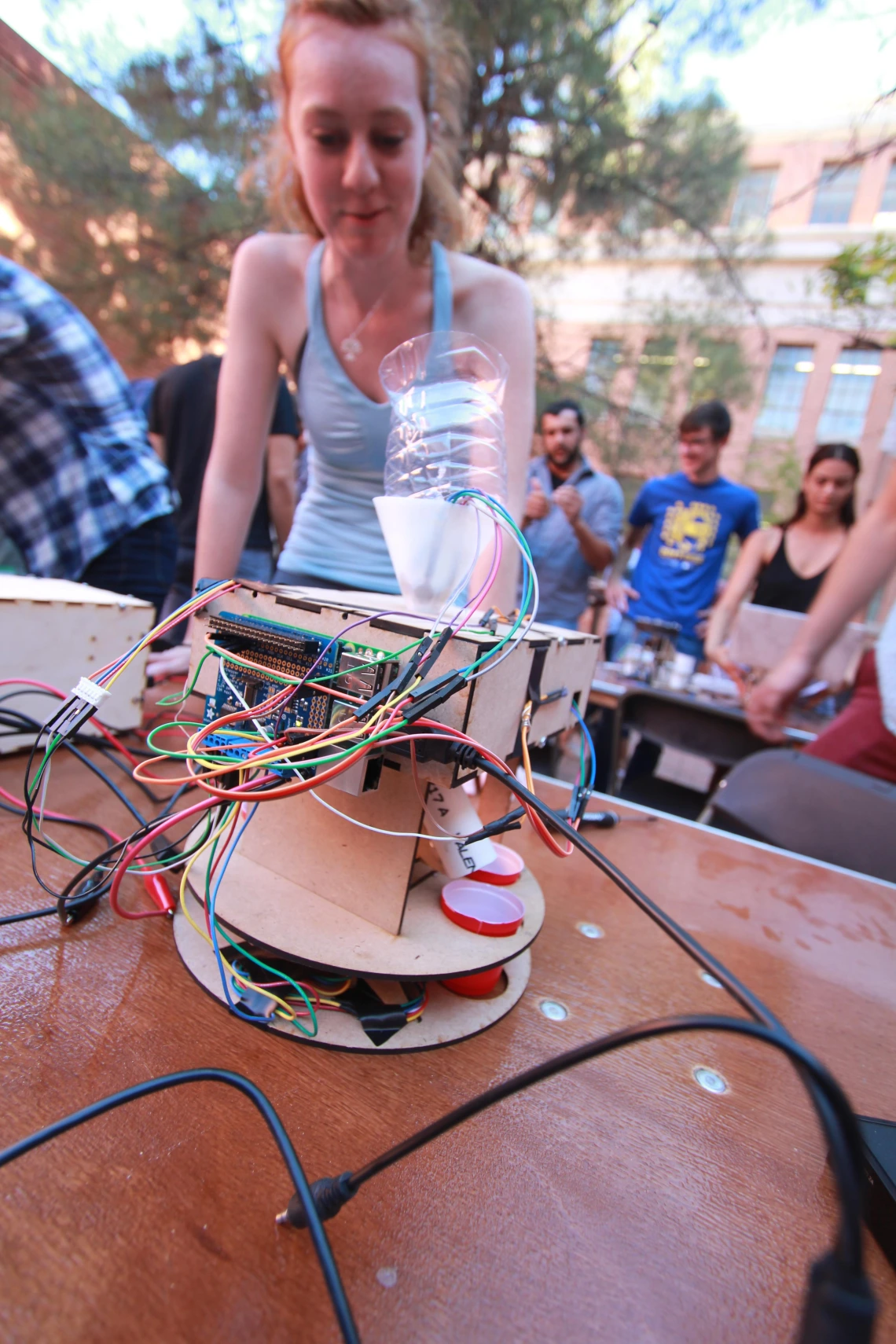

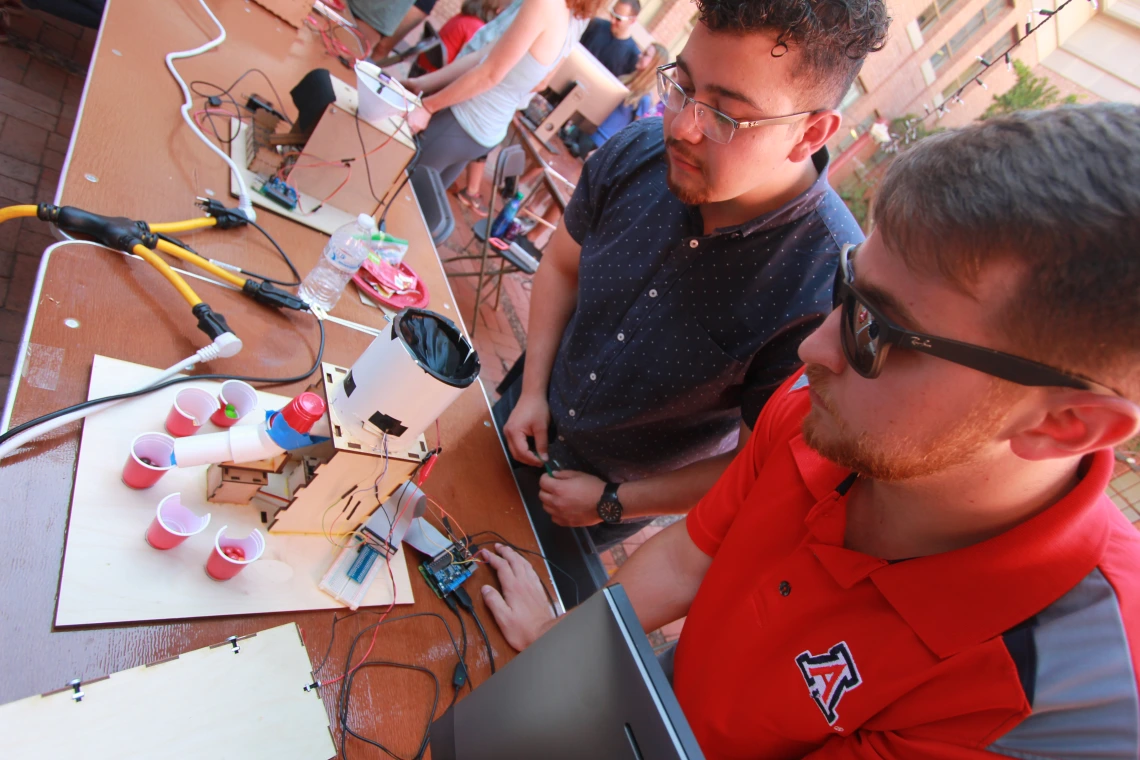

Students watch their Skittle-sorter in action.

University of Arizona biomedical engineering undergraduate Samantha Davidson spent her final class of the spring 2017 semester sitting in the sun sorting Skittle candies by color. “What a great way to end the semester!” she said.

Davidson was among 80 undergraduates, including 49 biomedical engineering sophomores, testing 36 Skittle-sorting machines their teams had created as part of a new design course. The challenge: accurately sort the highest number of Skittles in the least amount of time.

The competition was the culmination of a new undergraduate course for students in the College of Engineering’s biomedical engineering department and in the College of Social and Behavioral Sciences’ School of Information.

“I never had the experience before of using computer programming to design and build a working machine,” said biomedical engineering sophomore Alexys Manring. The experience will come in handy for her summer internship working on computer programming for irrigation systems for the U.S. Department of Agriculture.

The course is co-taught by Urs Utzinger, professor of biomedical engineering, and David Lesser, a UA graduate student who serves on the board of Xerocraft, a Tucson hackerspace and makerspace group. The course supports the College of Engineering’s commitment to incorporating hands-on design experience into the full undergraduate curriculum. The College plans to adapt it for its other undergraduate programs.

“We started with BME, since biomedical engineers design biomedical systems and products and must be familiar with the technical processes for maintaining them,” Utzinger said. Such equipment might include pill-sorting machines, which some of the Skittle sorters resembled.

Other competitors were juniors and seniors from the iSchool taking the corresponding creative coding course, taught by assistant professor Peter Jansen.

Solar Oven Throw Down to Skittle Sorter Showdown

UA Engineering freshmen take the introductory course ENGR 102 to learn fundamental concepts of modeling, design and construction. The course requires them to build solar ovens in teams, then compete to best predict their ovens’ performance at the Solar Oven Throw Down. Seniors participate in a capstone engineering design program, and display their sponsored projects at Design Day. Now sophomores have the maker course, which may also be adapted for juniors.

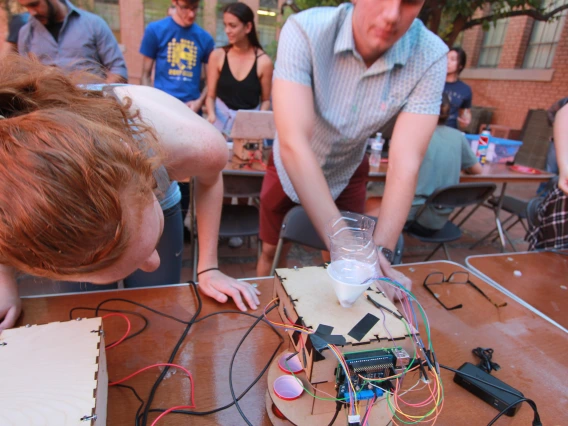

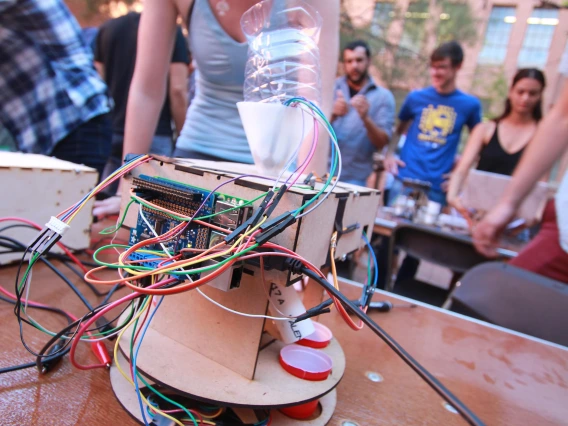

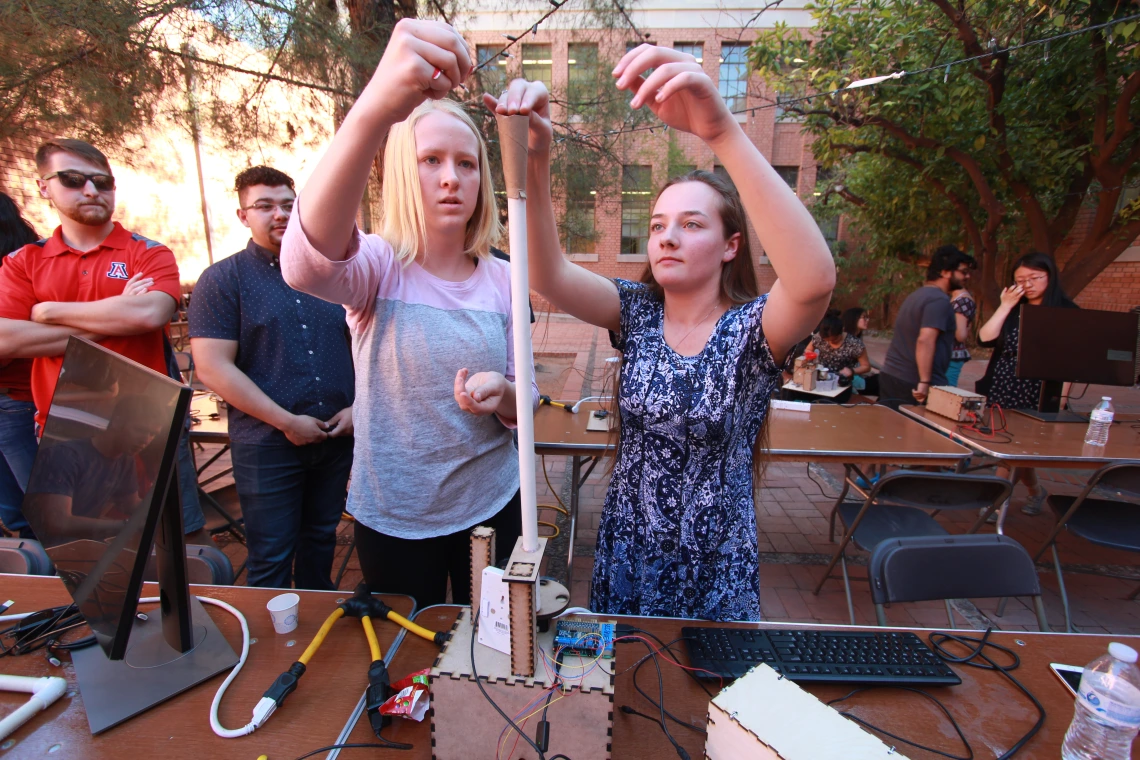

“Five-four-three-two-one … start your Skittle sorters!” Lesser shouted before each three-minute round of four competing teams. A cacophony rose up as students dumped packets of 60 Skittles into funneled hoppers and the candies cascaded down chutes for routing into one of five cups for red, orange, purple, yellow or green Skittles. Students made many of their components using 3-D printers and laser cutters. Microprocessors, servo actuators and power supplies kept the student-built machines humming.

Some teams encountered trouble with their systems for detecting the candies’ colors, but the failure was a valuable lesson in itself.

Their systems worked flawlessly inside the new makerspace created for the course, but were less responsive in the natural light of the Engineering Building courtyard, where the contest took place.

“We had programmed an image-processing system into our software to identify hues in the lab, but the values changed when we took the machine outside,” Davidson said.

“But isn’t that often the case?” said Lesser. “Practice sessions go smoothly, but at the crucial moment systems disappoint. It’s a fact of life for professional engineers.”

First and second place honors went to iSchool teams and biomedical engineering sophomores Isaac Russel and Katie Sosnowski took third place with their Skittle-sorting machine.