How Additive Manufacturing Can Transform Hypersonic Engine Technologies

Hypersonic weapons travel at least five times the speed of sound and are critical to U.S. national security measures. Advanced innovation is required to keep this type of technology nimble and agile. That’s why the SecureAmerica Institute (SAI) partners at Ursa Major Technologies are exploring how additive manufacturing, or 3D printing, capabilities can enhance the production of hypersonic engines as part of a SAI nationwide initiative to empower a secure U.S. defense industrial base.

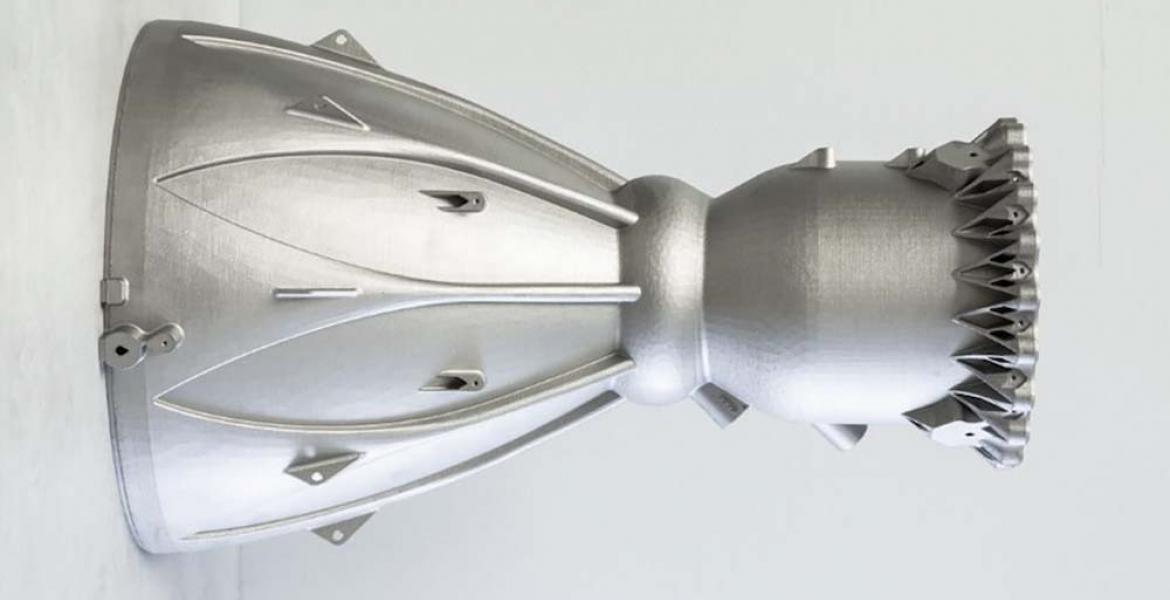

Propulsion systems are important components of hypersonic engines. These complex parts must work together seamlessly to ensure a high-performing and reliable system. According to research at Ursa Major, incorporating additive manufacturing into hypersonic production presents novel approaches to increase engine efficiency.

“Additive metallic manufacturing has the potential to address the critical need to create high-temperature parts with complex internal flow paths supporting the acceleration of propulsion engine design and technology,” said Erica Corral, associate professor of materials science and engineering at the University of Arizona and member of the governance board for the Texas A&M University Consortium for Applied Hypersonics. “Additionally, new opportunities for additive manufacturing of complex shape parts creates demand for research and development of reliable mechanical and thermal properties in these non-cast parts that are typically unique to their build and process.”