College of Engineering Names Philipp Gutruf 2024 da Vinci Circle Fellow

Associate professor creates revolutionary devices that integrate with biological systems – inside and outside the body – while prioritizing hands-on learning for students at the University of Arizona.

With expertise in neuroscience, materials science and hardware, Philipp Gutruf is looking 10 years into the future of health care and, with students at his side, inventing breakthrough medical devices that support personalized medicine.

As a boy in the Black Forest area of Germany – known for its production of high-end cars – Philipp Gutruf, the College of Engineering’s 2024 da Vinci Fellow, got his start tinkering on mopeds and electronics in the garage of his family home.

“That is not necessarily your typical academic path – getting the hands dirty,” said Gutruf, University of Arizona associate professor of biomedical engineering and associate department head of undergraduate affairs. “That gives you a different perspective on how you approach scientific problems.”

Now he is revolutionizing health care with biomedical devices for inside and outside the body. Generous donors to the College of Engineering’s da Vinci Circle select a fellow annually. The award comes with a one-time grant of $10,000 to support exceptional research in microtechnology, nanotechnology and biotechnology.

Personalized Health Care for All

From developing a technique for tracking neuron activity in the brain to creating wearable devices that ease the socioeconomic digital divide in health care, the Gutruf Lab is making significant inroads into equitable, streamlined and effective medical monitoring and treatment.

“We are interested in capturing the state of the body very accurately in order to treat, monitor and mitigate disease,” said Gutruf, also an inaugural Craig M. Berge Dean’s Fellow and member of the BIO5 Institute.

His implantable devices are at the forefront of how medical professionals will measure signals from internal organs. One tiny, wireless device uses light to communicate with neurons, nerve cells that transport messages from the brain to the body.

Gutruf’s battery-free optogenetic device illuminates neuron damage, bringing researchers a step closer to treatments for conditions such as chronic pain, depression and epilepsy.

Additionally, Gutruf’s lab is developing “sticker” sensors that doctors can one day place on bones during surgeries. The sensor sends data to the doctor, providing real-time measurements of a broken bone’s healing progress – without the need for scans.

“If you think about treatments and monitoring technology, we have X-ray and CT scans, but that’s been around for 20 years,” he said. “We can do therapy now that is absolutely tailored to the condition of your rehabilitation.”

On the digital front, Gutruf pioneered a 3D-printed, personalized, wearable device that uses sensors to monitor, for example, skin temperature and heart rate, but is not reliant on cellular infrastructure to send data.

“We have a lot of rural areas in the U.S. without coverage, and these types of devices are built to bring health care into areas where there is no access to a hospital – where there is no fancy monitoring machinery,” he said.

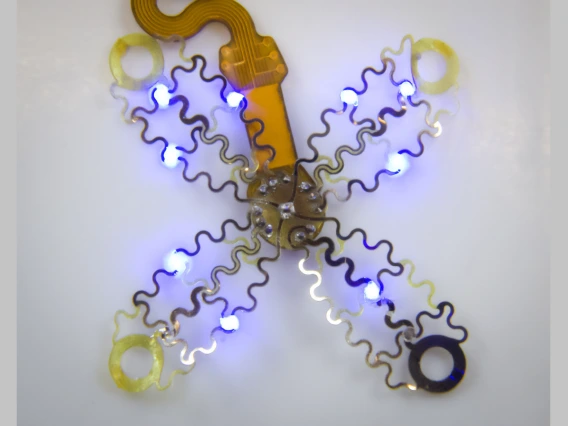

The soft, mesh-like device the lab calls biosymbiotic electronics continuously monitors biological signals and securely transmits data to health care providers up to 15 miles away. On the receiving end, the data provides information for predicting, diagnosing and treating a variety of conditions.

“He makes them convenient, comfortable, inexpensive – just available to everyone, which is what we need,” said Jennifer Barton, BIO5 director, Thomas R. Brown Distinguished Chair and biomedical engineering professor.

Gifts Foster ‘Engineering Dreamland’

Gutruf’s youthful tinkering and modest beginnings – mom was a teacher, dad a carpenter – coupled with highly regarded mentoring throughout his career keep him laser-focused on teaching hands-on skills to all his students.

“He loves to bring people up with him,” said Barton, who is impressed with her mentee’s teaching ability.

Gutruf joined the UA faculty in 2018 earning a PhD from the Royal Melbourne Institute of Technology and completing postdoctoral training at Northwestern University in Illinois.

Awards such as the da Vinci fellowship and philanthropic gifts – including one for developing the Peter and Nancy Salter Medical Device Design Lab – give Gutruf the resources to show students how to build, experiment and test their own wearable sensors.

“They allow professors to put students into engineering dreamland,” said Gutruf.

David Clausen, a biomedical engineering graduate student working in Gutruf’s lab agrees: “You have the ability to do research in the purist way; you can make mistakes and have the opportunity to expand your knowledge.”